Universal Synthetic Marine Gear Lube

Universal Synthetic Marine Gear Lube

True marine gear performance. Provides superior protection from shock loading. Resists foam and retains extreme-pressure qualities even when subjected to 10% water contamination. For use in outboard lower units, sterndrives, V-drives, bow and tunnel thrusters and marine transmissions Excellent for use in ATVs.

PRODUCT DESCRIPTION

AMSOIL Synthetic

Marine Gear Lube is an exclusive AMSOIL formulation

of synthetic base oils and high-performance

additives that address the specific concerns

of marine applications. It is fortified with extreme pressure

(EP) additives for superior protection

of fast-accelerating, high-torque/horsepower

engines. It protects against shock loading from

cavitation of heavily loaded engines.

AMSOIL Synthetic Marine Gear Lube is water resistant. It maintains extreme-pressure protection even when contaminated with as much as 10% water. It promotes longer seal life to help prevent water contaimantion. AMSOIL Synthetic Marine Gear Lube is designed to prevent rust and is compatible with aluminum, copper and brass alloys.

APPLICATIONS

AMSOIL Synthetic

Marine Gear Lube is recommended for fresh and

salt water applications requiring either 75W-90

or 80W-90 viscosity grade and meeting either

API GL-4 or GL-5 performance standards.

Examples of AMSOIL Universal Synthetic Marine Gear Lube applications include:

Outboard lower units: Mercury/Mariner, Johnson/Evinrude, Bombardier, Honda, Yamaha, Suzuki, Force/US Marine, Nissan, Tohatsu, Harbormaster Marine Outboard Drives, Sears Gamefisher and Seagull.

Sterndrives: Mercruiser-Bravo, OMC/Bombardier, Volvo-Penta, Yanmar, Konrad

Marine Drive Systems.

Bow & Tunnel Thrusters: Harbormaster Marine

Marine Transmissions: ZF Marine Transmission

AMSOIL Synthetic Marine Gear Lube provides:

- Excellent gear and bearing protection even when contaminated with 10% water

- Reduced friction and wear

- Rust and corrosion protection

- Long seal life

- Superior foam prevention

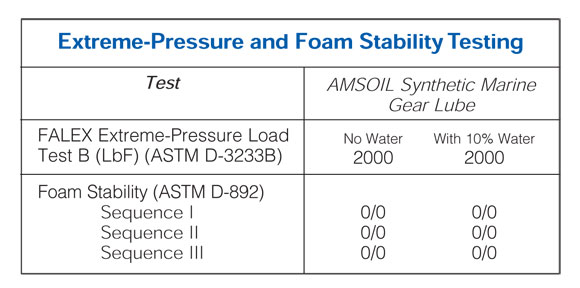

Marine gear oils operate in environments subject to water contamination. The chart demonstrates the ability of AMSOIL Synthetic Marine Gear Lube to maintain designed qualities such as extreme-pressure/anti-wear performance and resis-tance to foaming, even when subjected to 10 percent water contamination.

The Falex Procedure is a measurement of a gear lube's extreme-pressure and anti-wear properties. A high value in the Falex Extreme-Pressure Test relates to extra extreme-pressure protection. AMSOIL Synthetic Marine Gear Lube provides extreme-pressure protection and is highly resistant to the effects of water contamination.

The presence of foam in a lubricant disrupts oil film and promotes wear. Water contamination can increase the likelihood of foaming. Industry standard testing demonstrates zero foam in both new and water-contaminated AMSOIL Synthetic Marine Gear Lube.

AMSOIL Synthetic Marine Gear Lube is compatible with other commercially available conventional and synthetic marine gear lubes.

Follow manufacturers' recommended service intervals.

It is generally a good idea to change gear lube at the end of a season prior to storage.

AMSOIL Universal Synthetic Marine gear Lube is compatible with other commercially available conventional and synthetic marine gear lubes.

Follow manufacturers recommended service intervals.

It is generally a good idea to change gear lube at the end of the season prior to storage.

HEALTH & SAFETY

This product is not expected to cause health concerns when used for the intended

application and according to the recommendations in the Material

Safety Data Sheet (MSDS). USA and Canada (M)SDS are available upon request at 715-392-7101 or on the AMSOIL Website.

Keep Out of Reach of Children. Don’t pollute.

AMSOIL products are backed by a Limited Liability Warranty. For complete information visit Warranty Information

Kinematic Viscosity @ 100°C, cSt (ASTM D445) | 15.4 |

Kinematic Viscosity @ 40°C, cSt (ASTM D445) | 117.3 |

Viscosity Index (ASTM

D2270) | 137 |

Flash Point °C (°F) (ASTM D92) | 208 (406) |

Pour Point °C (°F) (ASTM D97) | -43 (-45) |

Falex Procedure B (ASTM

D3233) (failure load, LbF.) | 2000 |

Foam Stability (ASTM

D892) (20/50/20 maximum) | 0/0/0 |

- 55-Gallon Drum

- Quart Bottle

- 16-Gallon Keg

- 30-Gallon Drum

- 5-gallon Pail

- 10-oz. Tube

TheFSMO

TheFSMO